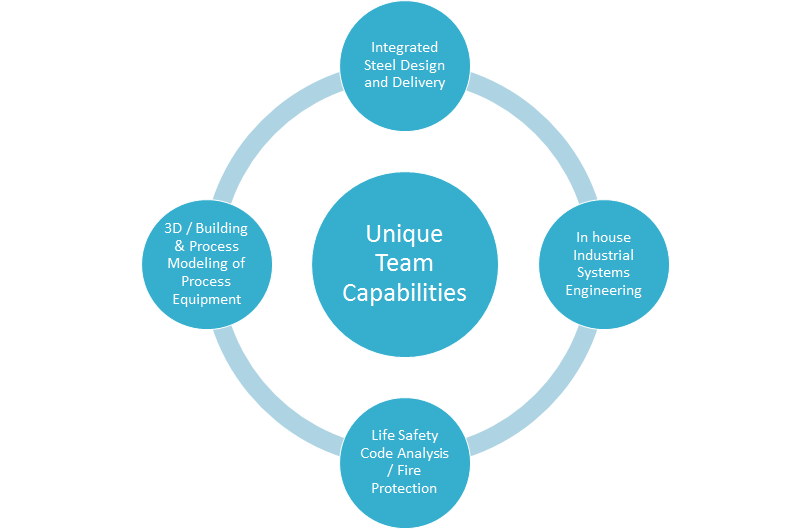

Thomasson Industrial Services (TIS) can provide several differentiating capabilities not common to typical A & E firms. Our strategic partnership can provide services to control and improve schedule as well as cost as well as improve on-going operations. These capabilities gives our team the ability to support your project from concept through construction and even production after the completion of a facility is complete. Our team’s decades of experience in industrial facilities is a differentiating factor. We bring the experience of not only the facility design but also operations.

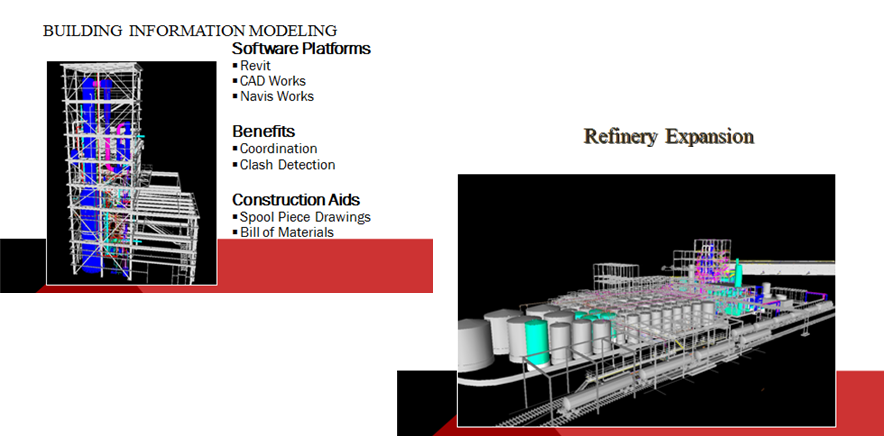

3D / Building & Process Modeling

TIS utilitzes 3D and Building Information Modeling (BIM) on all projects. This enables the team to work in real-time and coordinate even in cases where our team members may not be co-located in the same office. Our team even has experience developing Spool Piece Drawings and Bills of Materials for construction aids.

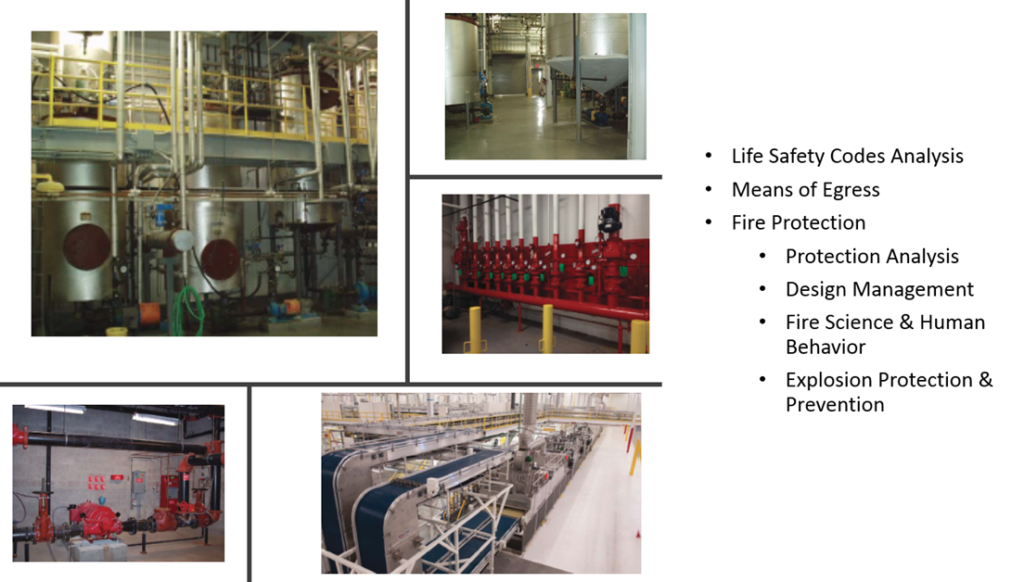

Life Safety Code Analysis & Fire Protection

Our expertise in Life Safety Code Analysis & Fire Protection has proven effective for our clientele in producing effective and code compliant results while delivering cost savings to the project. A facility is an asset which must be protected while providing a safe environment for the people in the building. TIS has the professionals you need to accomplish this task.

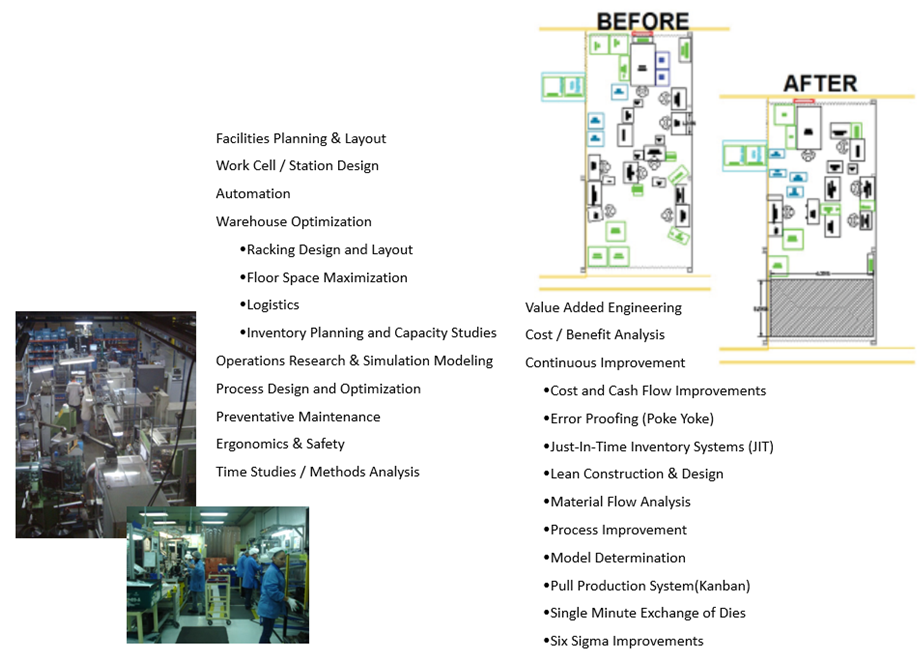

Industrial Systems Engineering

Integrated Steel Design and Delivery

TIS offers a unique approach to steel design. Our structural engineer partner is experienced working directly with steel fabricators to produce a 3D Building Information Model which can be shared during the design and fabrication process. This process also enables steel detailing to be completed much sooner in the and can include material lists, material tracking, CNC coding, fabrication shop and job site observations, and steel brokerage. This unique capability eliminates the need for drawing conversion for the different entities resulting in schedule savings and improved design quality. The results are improvements to the project for contractors and owners. Our team has demonstrated over 8 weeks of savings to projects using this distinctive process for our clients.

Contact Us for more information on how TIS can assist with all of your Architectural and Engineering needs.